China Prototyping: Revolutionizing the Manufacturing Landscape

In today's fast-paced business environment, the demand for rapid innovation and cost-effective production solutions has increasingly led many companies to explore various manufacturing options. One of the most prominent solutions emerging in the field of manufacturing is China prototyping. This article comprehensively explores the benefits, processes, and advantages of prototyping in China, particularly for businesses involved in metal fabrication.

Understanding Prototyping in China

Prototyping refers to the creation of a preliminary model or version of a product to test and refine its design before full-scale production. It is a crucial step in the product development cycle, allowing businesses to establish viability, functionality, and market demand. In China, prototyping has taken on a unique form, driven by the country’s technological advancements, skilled labor, and manufacturing infrastructure.

Why Choose China for Prototyping?

Companies worldwide have increasingly turned to China for their prototyping needs due to several compelling advantages:

- Cost-Effectiveness: China offers some of the most competitive pricing on prototyping services. The lower labor costs and efficient supply chains significantly reduce the overall expenditure for businesses.

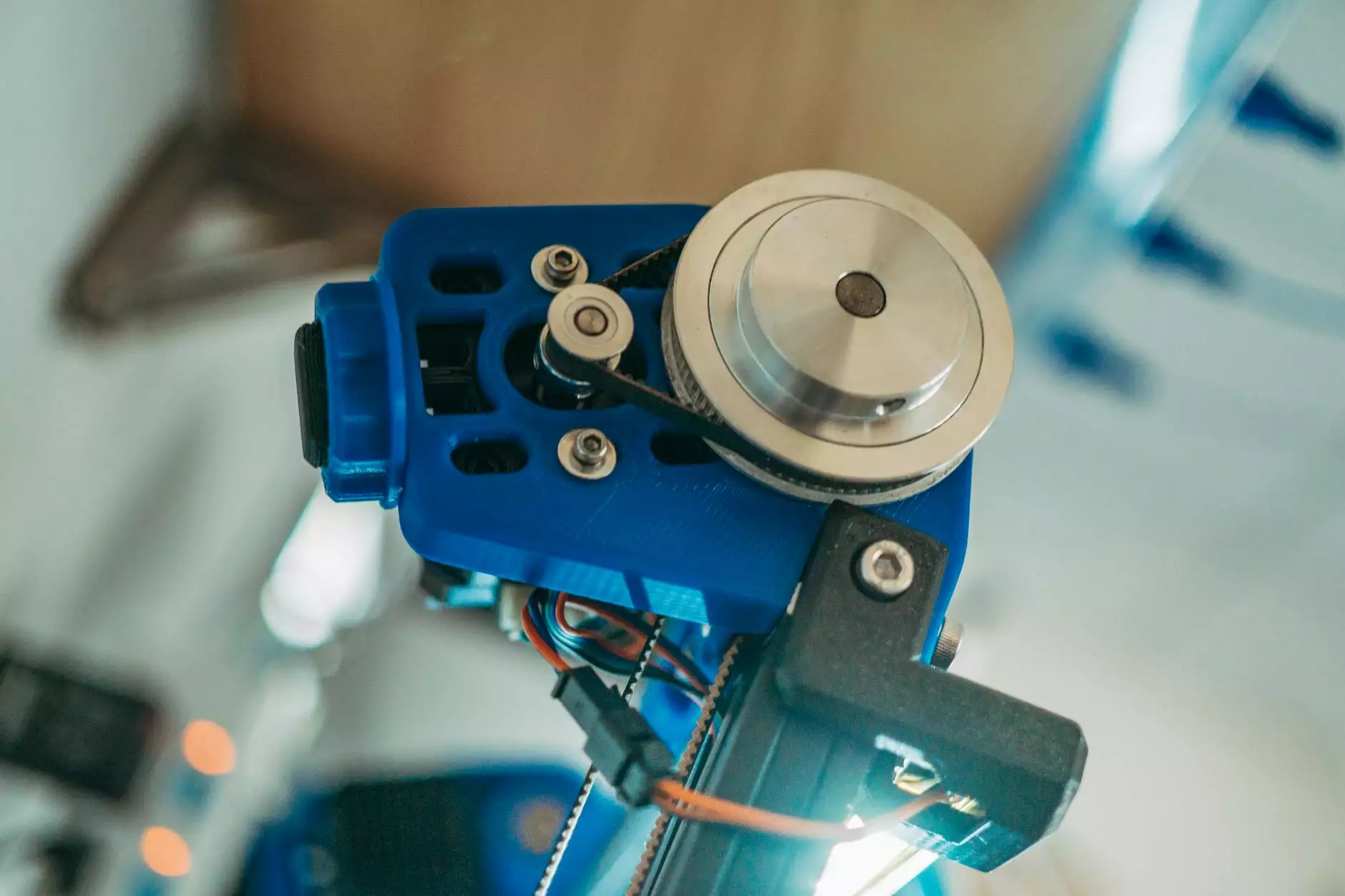

- Advanced Technology: Chinese factories often utilize cutting-edge technology, including CNC machining, 3D printing, and vacuum casting, ensuring high-quality prototypes efficiently.

- Rapid Turnaround Time: The speed at which prototypes can be developed and manufactured in China is unparalleled. Speed is crucial for businesses that need to bring products to market quickly.

- Skilled Workforce: China has a large pool of skilled engineers and designers experienced in various sectors, including metal fabrication, ensuring that your prototypes meet the required specifications and quality standards.

The Prototyping Process in China

The prototyping process can vary based on the specific needs of the business and the type of product being developed. Below is a typical framework of how China prototyping generally works:

1. Concept Development

Before any physical prototype is created, businesses should clearly outline their product concept. This encompasses design sketches, functional requirements, and specific material selections. A solid concept serves as the blueprint for subsequent prototyping stages.

2. Design Engineering

Once the concept is established, the next step involves detailed design engineering. Proficient engineers in China utilize advanced software tools (such as CAD software) to create intricate designs that can be translated into prototypes accurately.

3. Prototype Manufacturing

Following design finalization, the manufacturing phase commences. Depending on the product specifications, manufacturers might employ various techniques such as:

- CNC Machining: Ideal for creating precise components from metal or plastic.

- 3D Printing: Useful for rapid prototyping, allowing for complex designs that would be challenging to produce using traditional methods.

- Injection Molding: Suitable for producing multiple prototypes in a shorter timeframe, especially for plastic parts.

- Vacuum Casting: Effective for creating prototypes that mimic the properties of final production parts, especially in metal fabrication.

4. Testing and Refinement

After prototypes are produced, they undergo rigorous testing to evaluate their performance against design specifications. Feedback is collected, and necessary adjustments are made. This iterative process is vital in achieving a final product that meets market expectations.

5. Final Production Preparation

Once the prototype is refined and approved, manufacturers prepare for full-scale production. This step includes finalizing production plans, quality control measures, and supply chain logistics, ensuring a seamless transition from prototyping to full-scale manufacturing.

Benefits of China Prototyping for Metal Fabricators

For companies like DeepMould.net, which specialize in metal fabrication, the advantages of utilizing China prototyping can be particularly significant:

1. Enhanced Design Flexibility

Metal fabricators can experiment with various designs and materials. China’s flexible manufacturing capabilities allow for adjustments to be made quickly during the prototyping phase, ensuring that the final product aligns perfectly with the client’s vision.

2. Access to Advanced Resources

Many Chinese manufacturers are equipped with advanced technology specifically designed for metal prototyping, such as high-precision laser cutting and welding machines. This access enables firms to achieve better quality and higher tolerances in their prototypes.

3. Shortened Time to Market

Rapid prototyping is an essential service for businesses looking to stay ahead of the competition. By utilizing China’s resources, metal fabricators can reduce their product development time, enabling them to introduce new products more quickly and efficiently.

4. Comprehensive Support Services

Many prototyping companies in China provide additional support services such as sourcing materials, logistics, and quality assurance. Such services can help streamline the entire process from initial design to final production, offering businesses a holistic solution to their prototyping needs.

Success Stories: Transforming Ideas into Reality

Numerous global companies have successfully leveraged China prototyping to take their products from concept to market. Here are a few notable examples:

Case Study 1: High-Tech Gadget Manufacturer

A high-tech gadget manufacturer faced challenges in quickly iterating designs while controlling costs. By utilizing a Chinese prototyping service, they reduced their prototype development time by over 50%, allowing them to launch their innovative product well ahead of their competitors.

Case Study 2: Automotive Parts Producer

An automotive parts company required precision-engineered components for new vehicle models. Partnering with a Chinese manufacturer specialized in metal fabrication allowed them to achieve unprecedented quality and accuracy, which directly contributed to increased consumer satisfaction and sales.

Overcoming Challenges in China Prototyping

While the benefits are substantial, there are challenges businesses may encounter when opting for China prototyping. Here are key considerations to keep in mind:

1. Communication Barriers

Language differences can sometimes hinder effective communication. It’s crucial to work with a prototyping partner who is proficient in English to ensure that all project specifications are correctly interpreted and executed.

2. Quality Control Issues

Not all manufacturers maintain the same quality standards. Companies should conduct extensive due diligence to verify the reputation and quality certifications of potential partners, ensuring they meet industry standards.

3. Intellectual Property Risks

Protecting intellectual property (IP) is vital when sharing designs with manufacturers. Businesses must take the necessary steps to safeguard their IP through non-disclosure agreements (NDAs) and legal contracts.

Choosing the Right Prototyping Partner in China

When selecting a prototyping partner in China, consider the following criteria:

- Expertise and Experience: Look for manufacturers with extensive experience in your industry, particularly in metal fabrication.

- Technology and Equipment: Assess whether the prototyping partner has access to modern technology that aligns with your prototyping needs.

- Portfolio and References: Review their past projects and seek client references to gauge their reliability and quality.

- Communication Skills: Ensure that the team is responsive and can communicate effectively throughout the prototyping process.

- Location: Consider the geographical advantages of working with a manufacturer that is strategically located near key suppliers or logistics hubs.

The Future of Prototyping in China

As technology continues to evolve, the future of China prototyping looks promising. With advancements in artificial intelligence, machine learning, and automation, prototyping processes are likely to become even more efficient and accurate. Companies like DeepMould.net are well-positioned to leverage these innovations to enhance their offerings in the metal fabrication sector, ensuring that they stay ahead in a competitive landscape.

Conclusion

In conclusion, China prototyping stands as a beacon of opportunity for businesses aiming to innovate and reduce production costs. By harnessing the advantages of rapid prototyping, advanced technology, and a skilled workforce, companies can transform their ideas into reality while ensuring high-quality outputs. Whether you're a startup or an established organization, partnering with experienced prototyping specialists in China could significantly impact your product development journey.

As the landscape of manufacturing continues to evolve, embracing China prototyping could very well be the key to unlocking new levels of efficiency and success for your business.